CHEMICAL CLEANING IN INDUSTRIAL ENTERPRISES

PRE-START CHEMICAL CLEANING IN PLANTS UNDER CONSTRUCTION

- ABOUT SERVICE

- BIORENEX PRODUCTS

- PUMPING EQUIPMENT

- PHOTO/VIDEO

- COOPERATION WITH US

It’s safe chemical cleaning technology from scale and corrosion for heat exchangers, evaporators, cooling jackets of industrial enterprises.

BIORENEX — is brand new effective and absolutely safe of chemical cleaning technology of heat exchangers, evaporators, cooling jackets from scale and corrosion.

It is important to note that:

— the product has all the necessary legal documents for use in Russia and Europe

— the product is certified by the GOST

We provide services for cleaning, rinsing and washing of heat exchange systems at the customer's site by using our own repair base, available equipment and experienced group of maintenance services.

Washing and pickling of heat exchangers handed in for repair.

Pipelines, steam pipelines, product pipelines, equipment, etc., are subjected to pre-start washing to clear them of any technical greases, oils, rust, scale and welding marks at the industrial enterprise. This is followed by the pacification of treated interior surfaces. Work is performed according to the customer's washing program.

Descale and restore flow, cumulative heat exchangers and water heaters of all types, including:

- compressors, condensers, injectors

- evaporators, fractioning columns, cooling jackets, refrigerators

- cooling systems of compressors of methane, oxygen, air, nitrogen and similar equipment

- shell-and-tube, plastic, spiral and other heat exchangers

- heaters

- reheaters

- boilers.

We work in all areas of the industry:

- Petrochemical and oil refinery plants

- Cardboard and paper mills

- Nuclear power plants

- Metallurgical enterprises

- Sea and river vessels

- Food industry: sugar factories, breweries, juice production factories, dairy factories, confectionery production factories, alcohol beverages production factories

- Other enterprises with heat exchangers.

Biorenex products are reagents and catalysts for the industrial sector.

BIORENEX-S REAGENT

Biorenex-S reagent is designed for chemical washing in terms of solution circulation at an elevated temperature of 40-50 C.

| Grey cast iron | |

| Stainless steel | |

| Carbon steel | |

| Enameled steel | |

| Galvanized steel | |

| Copper alloys | |

| Aluminum alloys | |

| Zinc |

BIORENEX-K REAGENT

Biorenex-K reagent is a special product that used in specific conditions where we are dealing with scales resistant to Biorenex-S, B products.

| Grey cast iron | |

| Stainless steel | |

| Carbon steel |

BIORENEX NEUTRALIZER

Biorenex neutralizer is designed to neutralize Biorenex products before draining them into the sewer.

| Grey cast iron | |

| Stainless steel | |

| Carbon steel | |

| Enameled steel | |

| Galvanized steel | |

| Copper alloys | |

| Aluminum alloys | |

| Zinc |

BIORENEX-B REAGENT

BIORENEX-B reagent is designed for chemical treatment in terms of solution circulation.

| Type of reagent | Liquid |

| Packaging | Can |

| Weight | 5 kg / 10 kg / 25 kg |

| Grey cast iron | |

| Stainless steel | |

| Carbon steel | |

| Enameled steel | |

| Galvanized steel | |

| Copper alloys | |

| Aluminum alloys | |

| Zinc |

-

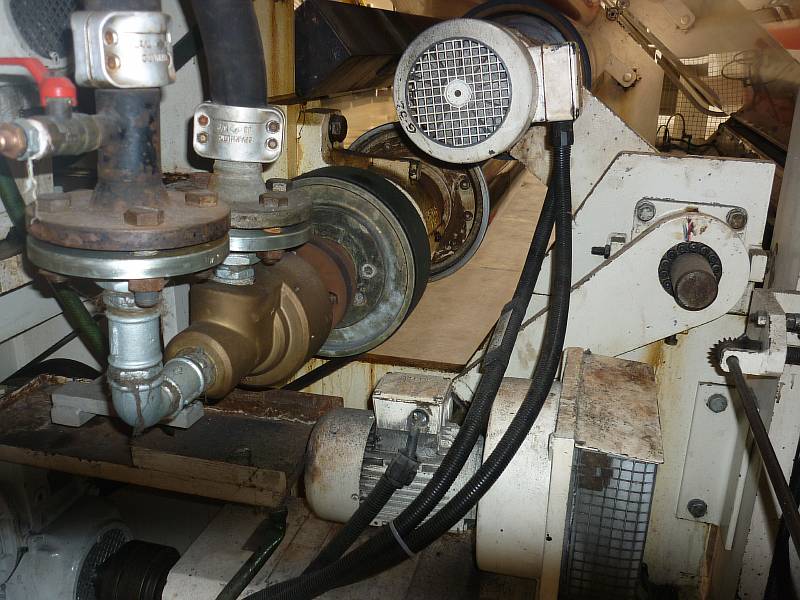

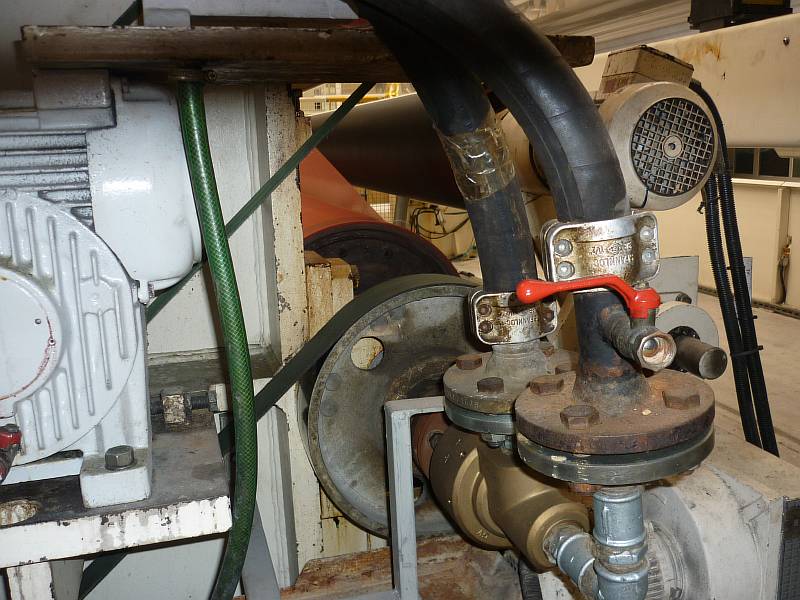

Apply one of our recommended chemical pumps for compliance. They use the latest technology for the flushing of district heating systems and industrial heat exchangers.

The installation of a pump during the chemical flushing process guarantees:

- Support the proper temperature of the solution;

- Support of adequate circulation of the liquid jets in the system;

- Proper distribution of product in the cleaned system;

- Effective leaching of dissolved sediment, rust and scale;

- A simple way to change product flow direction in the cleaned system.

The use of BIORENEX product for flushing the system always gives measurable benefits. Carrying out the flushing in accordance with recommended technology allows us to achieve the best results using our designed chemical pumps.

OUR PUMPS

We also offer rental services of the equipment regardless of whether you purchase a pump. We offer equipment rental for customers who buy the product but do not have their own equipment and want to clean their systems.

Beer production plant

Aircraft manufacturing plant, flushing of oil cooler of the compressor

Execution of works at the plant for the production of mineral fertilizers

Juice plant

The process of cleaning the cooling line of rolls and heat exchangers

Katowice compressor

Video

-

For companies operating in industries:

- repair and maintenance of heat exchangers,

- repair and maintenance of district heating networks,

- installation and maintenance of individual heating units,

- repair and maintenance of valves,

- repair and maintenance of industrial boilers,

- installation, start-up and maintenance of boiler equipment,

- commissioning works at industrial plants,

- repair and maintenance of pumps,

We are ready to offer cooperation in chemical cleaning with the use of our equipment and BIORENEX reagents.

We offer advantageous conditions for cooperation, a comprehensive briefing on the proposed cooperation and preferential conditions for the purchase (lease) of pumping apparatus, as well as BIORENEX liquids for all partners.

We offer cooperation in maintenance and flushing of deposits from any origin that result during the operation for enterprises that use heat-transfer equipment (chillers, condensers, evaporators, fractioning columns, cooling jackets, refrigerators, heat exchangers of any design, etc.). Our experts will conduct a comprehensive analysis of the deposits occurring in equipment and then present the best way to remove them. We can even train your specialists in the use of our technology.

We'll restore the heat-exchange and production characteristics of equipment to save resources, avoid costly repairs, prevent unforeseen equipment replacement and limit long downtime that costly repairs can incur.